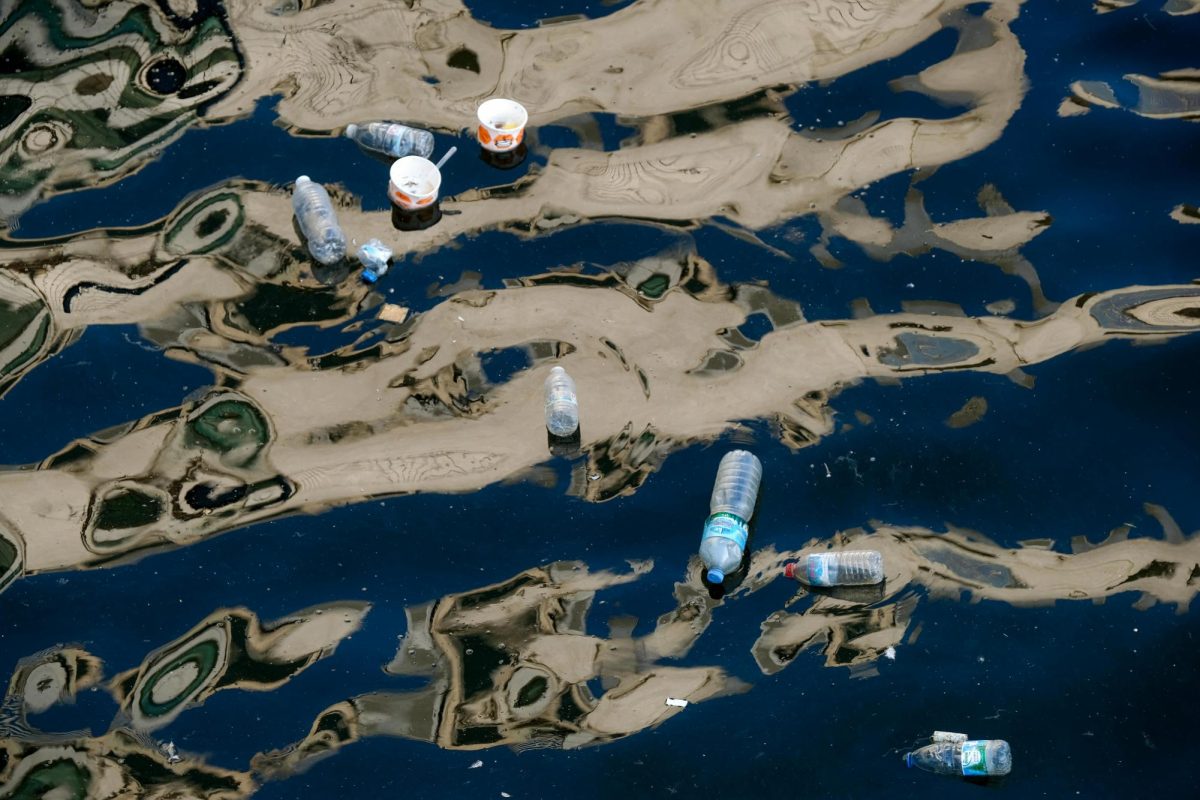

Direct air capture (DAC) is emerging as a promising strategy in the fight against climate change, particularly in achieving carbon neutrality (Zhou et al., 2024). Robert Sanders, science communications manager at UC Berkeley, states that the inexorable rise of atmospheric CO2–now 50% higher than pre-industrial levels–necessitates innovative approaches to reverse this trend. While conventional carbon capture (CC) technologies excel at concentrated sources, they struggle with the diffused CO2 concentrations in ambient air (Sanders, 2024). This disparity demands advanced methods capable of efficiently extracting CO2 directly from the atmosphere. A recent breakthrough offers a promising avenue: the development of a durable and efficient covalent organic framework (COF) capable of capturing CO2 from open air (Sanders, 2024; Zhou et al., 2024).

The Discovery of COF-999 and Its Capture Mechanism

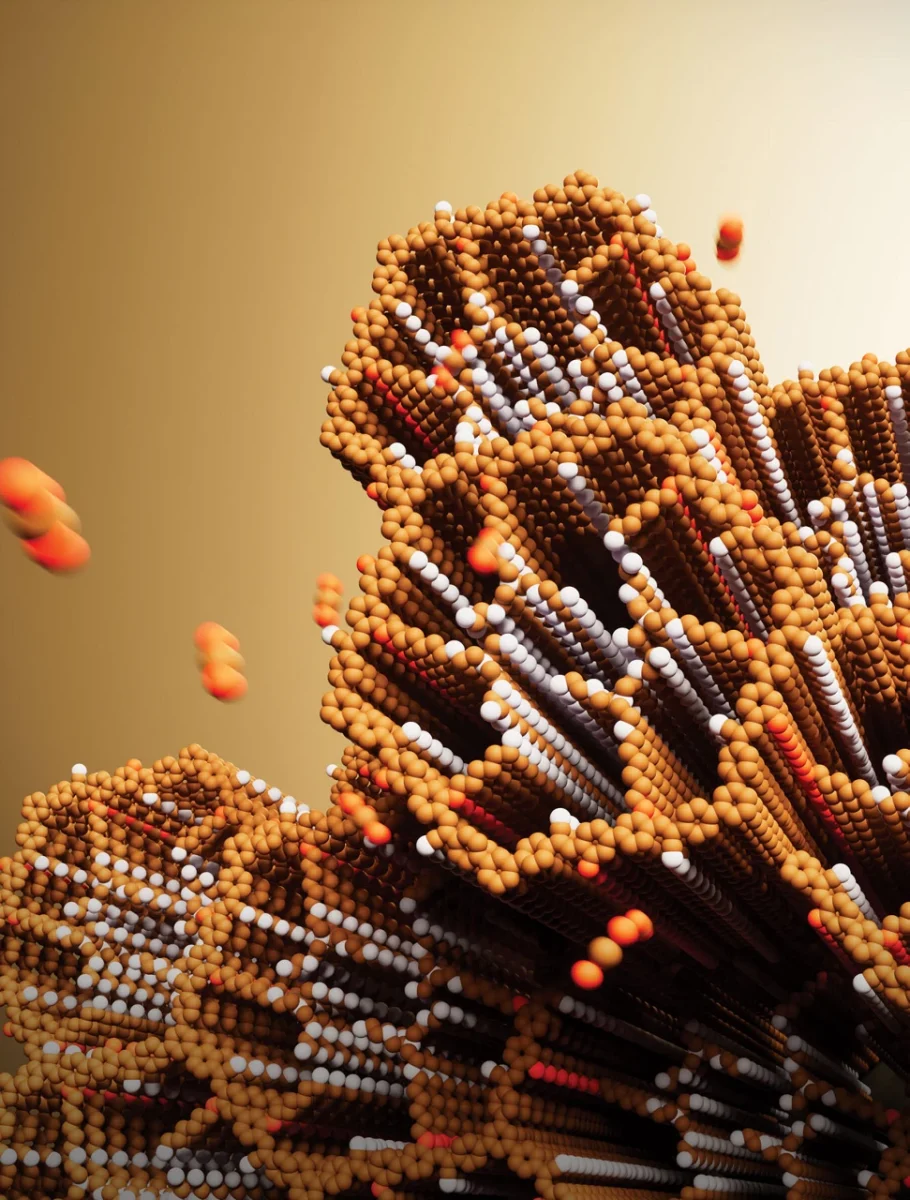

Researchers at the University of California, Berkeley, alongside teams in Germany and Chicago, engineered COF-999, which demonstrates exceptional performance in DAC (Sanders, 2024). This material features olefin linkages and amine initiators that generate polyamines within its pores (Zhou et al., 2024). This ingenious design significantly enhances COF-999’s affinity for CO2, enabling it to effectively capture the greenhouse gas from ambient air (Foley, 2024). As lead researcher Omar Yaghi notes, the material “cleaned the air entirely of CO2” in initial tests (Sanders, 2024). Computational modeling further revealed that the amine-functionalized framework selectively binds CO2 over other gases (Foley, 2024) through an acid-base reaction in which the amine polymers trap CO2 molecules (Barbu, 2024).

The Performance and Stability of COF-999

COF-999 exhibits remarkable CO2 capture efficiency, reaching 0.96 mmol g-1 in dry conditions and 2.05 mmol g-1 at 50% relative humidity, both at a CO2 concentration of 400 ppm (Zhou et al., 2024). What sets it apart is its stability and durability (Foley, 2024). It maintains its performance over at least 100 adsorption-desorption cycles (Zhou et al., 2024), an attribute for long-term application. Unlike many porous materials, COF-999 resists moisture degradation; small amounts of water can even enhance its CO2 capture capacity by promoting carbamate and bicarbonate formation (Barbu, 2024). Moreover, the material boasts a low regeneration temperature of 60 °C (Zhou et al., 2024), reducing the energy requirement for CO2 release and subsequent reuse. This combination positions COF-999 as a promising candidate for widespread deployment in DAC systems.

The Implications on Our World

COF-999’s stability, rapid CO2 uptake–reaching half capacity in just 18.8 minutes (Zhou et al., 2024)–and low energy demand address key limitations of existing DAC methods. As Zhou et al. point out, a mere 200 grams of COF-999 can absorb as much CO2 as a tree (2024). According to Brianna Barbu (2024), production editor of C&EN, the modularity of COF structures allows further optimization. Researchers are already exploring ways to enhance COF-999’s CO2 uptake capacity and develop cost-effective manufacturing processes (Barbu, 2024), such as solvent-free synthesis routes, to improve sustainability (Heinrich-Heine, 2024). While some experts caution that challenges remain–such as optimizing CO2 recovery in complete DAC systems–Yaghi and his team remain confident in the effectiveness of COFs in widespread CC applications (Barbu, 2024).

Conclusion

The development of COF-999 represents a significant step forward in the quest for effective and scalable DAC technologies. Its unique combination of stability, efficiency, and ease of regeneration positions it as a potentially transformative material in the fight against climate change (Zhou et al., 2024). As research progresses and as innovative materials like COF-999 are integrated into existing and future CC systems, the prospect of achieving negative emissions and reversing the rise of atmospheric CO2 inches closer to reality (Sanders, 2024). The challenge now lies in scaling up production, optimizing performance, and deploying these materials in ways that maximize their impact on global carbon reduction efforts.